Nylon

Semi-crystalline polymer Nylon has goods general features and excellent quality/price rate. Using only high viscosity raw material for the extrusion of our Nylon 6 stock shapes grants a very high quality level: mechanical resistances as well as sliding properties are higher if compared with other low viscosity Nylons. Our unique annealing process grants dimensional stability and easy machining.

Full detailsFluoropolymers (PTFE, PVDF, PCTFE, PFA)

PTFE, or Polytetrafluoroethylene, or Teflon is a synthetic fluoropolymer known for its non-stick, lowest-frictional properties. With its superb chemical and dielectric properties, it is widely used in the petrochemical and pharmaceutical industry.

Full detailsAcetal Copolymer (OmniAcetal)

Overview

Polyoxymethylene, commonly called Acetal, is a crystalline polymer obtained from the polymerisation of formaldehyde. Discovered fairly recently (1960), it has enjoyed rapid growth and large acceptance thanks to its excellent mechanical features, stability to humidity and ease of machining. All our stock shapes made of POM are marked along the whole length with product code and batch number, according to ISO standards.

Full detailsAcetal Homopolymer (Delrin)

Overview

The general features of the homopolymer Acetal resin are similar to those of the copolymer POM-C. However, the service temperature (under load) is slightly higher but the resistance to hydrolysisis and strong alkalis is slightly lower. POM-H is more commonly known as Delrin®. POM-H has a slightly higher mechanical strength than the POM-C but both are easy to machine and offer excellent dimensional stability.

Full detailsPET-P (Arnite & OmniaLite)

Overview

Arnite is a relatively new semi-crystalline polymer developed for technical applications. It is suitable for mechanical parts which require dimensional stability and a low friction coefficient. Omnialite is a modified PET designed to provide a higher shock resistance than Arnite by reducing the E-modulus.

Full detailsCast Nylon PA6G (OmniAmid)

Overview

Cast Nylon 6. The method of production of this polyamide (i.e. the polymerisation of the caprolactam directly in the mould) allows the production of stock shapes in larger than normal dimensions, such as big rings or very thick sheets. The general features are similar to those of Nylon 66.6, which means that it is stiffer and more brittle than extruded Nylon.

Full detailsPolyethylene PE300 & PE1000 rod

PE300 also known as HDPE, High Density Polyethylene, is a more cost effective and easier to weld product compared to PE500 & PE1000. Its flexibility and ease to process makes excellent also for forming. Widely used in fabrication and basic mechanical parts.

Full detailsPolyethylene PE500 Sheet

PE500 also known as HMWPE, High Molecular Weight Polyethylene, has a high impact strength supported by good abrasion and chemical resistance. Mainly used in repetitive applications wear food contact are concerns.

Full detailsPolyethylene PE1000 Sheet

PE1000 also known as UHMWP, Ultra High Molecular Weight Polyethylene, has exceptional wear resistance, low friction and high impact strength at temperature as low as -150°C long term, possible -200°C short term.

Full detailsPolypropylene

Overview

Polypropylene provides excellent resistance to organic solvents, degreasing agents and electrolytic attack. It has a lower impact strength, but its working temperatures and tensile strength are superior to low or high density polyethylene. It is lightweight, resistant to staining, and has a low moisture absorption rate. This is a tough, heat-resistant, semi-rigid material, ideal for the transfer of hot liquids or gases. It’s recommended for vacuum systems, where higher heats and pressures are encountered.

Full detailsPVC (U-PVC)

Overview

PVC has high hardness, good mechanical properties, high tensile strength and excellent chemical resistance. It is self-extinguishing and has class 1 fire rating. This is vital for construction applications and making flat sheet PVC ideal for wall cladding applications and hygienic-cladding. It has good electrical properties in the low voltage and frequency range. This tough plastic can be easily fabricated, welded and bonded together with solvent cements making it one of the most versatile plastics available.

Full detailsPEEK

Overview

PEEK is considered the most popular advanced engineering plastic with a unique combination of high mechanical properties, temperature resistance and excellent chemical resistance. VICTREX® Polyetheretherketone polymers are high quality products in a wide range of AEPP’s.

Full detailsPhenolic Cotton Laminates

Overview

This material is made by applying heat and pressure to layers of Super Fine Weave Cotton and synthetic resin. When heat and pressure are applied to the layers a chemical reaction (polymerization) transforms the layers into a high-pressure thermosetting industrial laminated plastic

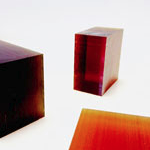

Full detailsAcrylic Cast

Overview

Acrylic is polymethyl methacrylate (PMMA), which is sold under the brand names of Plexiglas, Lucite, Perspex, and Crystallite. PMMA is a tough, highly transparent material with excellent resistance to ultraviolet radiation and weathering. It can be coloured, moulded, cut, drilled, and formed.

Full detailsPolycarbonate

Overview

Polycarbonate material is formed by a condensation polymerization resulting in a carbon that is bonded to three oxygen atoms. It’s a transparent, strong and stiff thermoplastic material with outstanding impact resistance.

Full detailsABS

Overview

Acrylonitrile Butadiene Styrene (ABS) is the polymerization of Acrylonitrile, Butadiene, and Styrene monomers. Chemically, this thermoplastic family of plastics is called “thermopolymers”, in that they involve the combination of three different monomers to form a single material that draws from the properties of all three. ABS can be used in temperatures ranging from -50°C to +70°C

Full detailsNoryl

Overview

The NORYL family of modified PPE resins consists of amorphous blends of PPO™ resin (polyphenylene ether) and polystyrene. They combine the inherent benefits of PPO resin (affordable high heat resistance, good electrical properties, excellent hydrolytic stability and the ability to use non-halogen FR packages), with excellent dimensional stability, good processibility and low specific gravity. NORYL resins offer a good balance of mechanical and chemical properties, and may be suitable for a wide variety of applications.

Full detailsPolysulphone PSU

Overview

PSU is a semi-crystalline polymer. It’s a material with high mechanical and thermal properties (up to 240°C.). It resists to creep under load and to wear, its friction coefficient is low. The temperature resistance without load is high but it is reduced by the addition of load even if limited.

Full detailsPEI Ultem 1000

Overview

Ultem is a high performance engineering plastic offering high mechanical and electrical properties as well as excellent flame and heat resistance. It is UL94 VO rated (self-extinguishing) and USP Class VI compliant. Capable of withstanding repeated autoclaving cycles. Maximum continuous operating temperature is 170°C.

Full details